Introduction

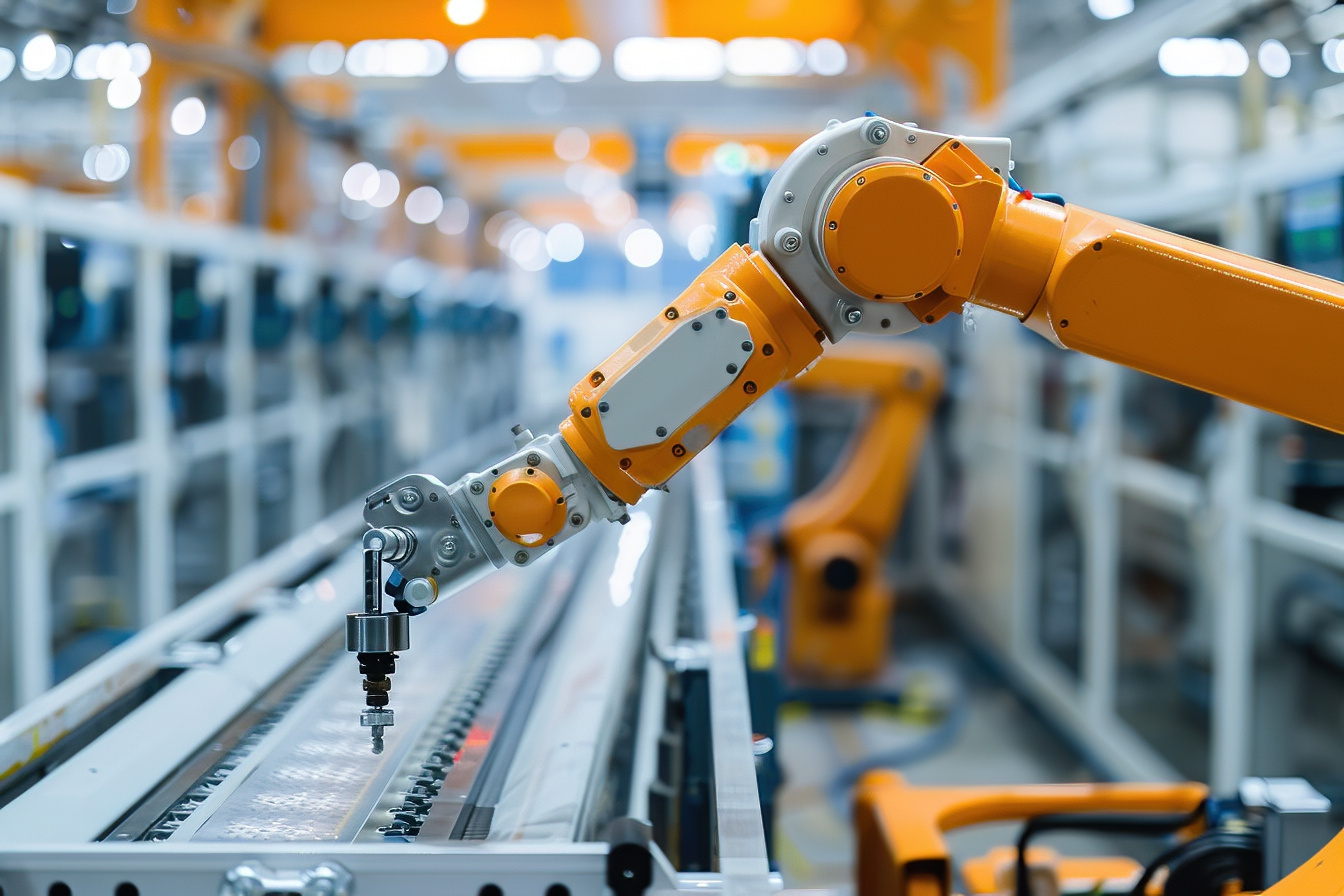

Micro switches can be found in various control systems of factory assembly lines, emergency stop operations of machine tools, and travel detection of automated machinery. With their reliable triggering performance, micro switches have become the key components for ensuring the safe operation of industrial equipment. In industrial scenarios, where equipment operates at high speeds and conditions are complex, there are potential risks such as over-travel and accidental operations. However, micro switches effectively avoid these risks through precise signal transmission and rapid response.

The function performed by the microswitch

The housing adopts an IP65 dustproof and waterproof structure, which can resist the erosion of workshop dust and oil, and prevent triggering failure caused by environmental factors. In the emergency stop system of machine tools, the response time of micro switches is at the millisecond level. After pressing the emergency stop button, the power supply of the equipment can be instantly cut off to prevent accidents from escalating. On the conveyor belt of the assembly line, it achieves precise start and stop by detecting the position of the workpiece, reducing equipment idling and collision losses.

Conclusion

A person in charge of an automotive parts processing factory stated that after replacing all the equipment in the workshop with industrial-grade micro switches, the accident rate caused by limit control failure or emergency stop failure dropped from 4.2% to 0.3%, and the continuous operation time of the equipment increased by 20%. With the advancement of Industry 4.0, domestic micro switches, with stable performance, have been widely applied in mechanical manufacturing and automated production lines, safeguarding the safety of industrial production.

Post time: Nov-18-2025